產品說明:

Introduction

YLW系列有機熱載體爐為組裝式強制循環鏈條爐排鍋爐。鍋爐本體前部為爐膛輻射受熱面,由密排的雙方形盤管構成;后部為對流沖刷受熱面,由蛇形管束組成。鍋爐由上部本體和下部鏈條爐排組成,工地現場組合。空氣預熱器布置在鍋爐后面。燃燒生成的高溫煙氣在爐膛被吸走部分熱量,經轉向煙室進入對流受熱面換熱,出鍋爐后在空氣預熱器中加熱鍋爐燃燒所需的空氣,再經除塵器由引風機將煙氣送至煙囪排入大氣。

產品特性:

·安裝方便,只要上部本體和下部排爐合攏即可,安裝周期短。

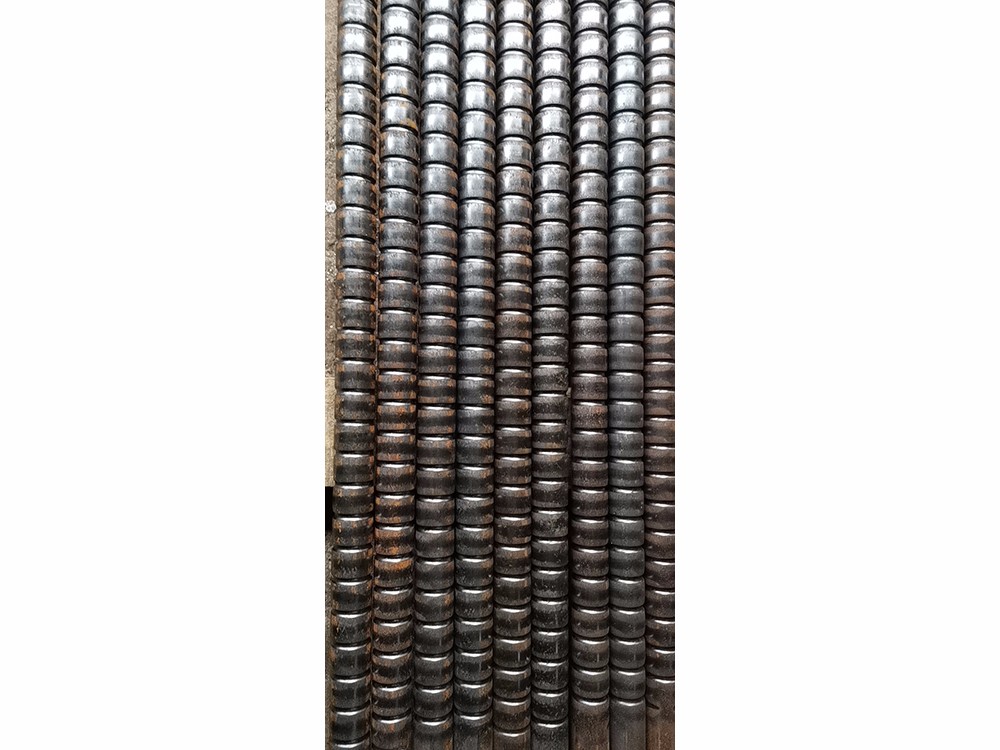

·爐膛采用雙密排盤管,受熱面布置充足,降低管子表面熱負荷,是導熱油使用更安全。

·介質流程合理,導熱油由低(進口)到高(出口),運行中產生的氣體很難在爐內停留,可方便的排出系統。

·爐拱設計合理,煙氣在爐膛內停留時間長,燃燒更充分。

·轉向煙室布置受熱面,使隔墻避免高溫煙氣直接沖刷,有效防止隔煙墻脫落產生的煙氣短路現象。

YLW organic heat-medium boiler is the packaged forced circulation chain grate boiler.Front section of boiler body is the hearth radiation heating atea consisting of closely-aligned double-square coils.The rear section is the convection flush heating area of coil tube bank.Boiler is structured into the body drum on the combustion hot fume chamber.Heat from the boiler is used to heat the air as required for the boiler combustion in the air pre-heater.Then fume exhausts outside with chimney via th dust collector and draught fan.

Simple installation and short installation period.Just combine the upper body and lower conbustion chamber.

Himple consists of double closely-aligned coils to ensure the sufficient heating area, reduce the surface heat load of pipe and handle the heat transfer oil safely.

Reasonable medium flow.Heat transfer oil flows from the lower inlet to the upper outlet.Gas generated during the operation stays in the boiler hardly and can exhaust easily.

Sound design of boiler vault.Fume can stay in the hearth long enough for better combustion.

Heating area in the dibersion fume chamber.Use the divisions to avoid direct flushing from hot fume and to effectively prevent the fume short circuit from the falling fume divisions.

產品范圍:

Scope

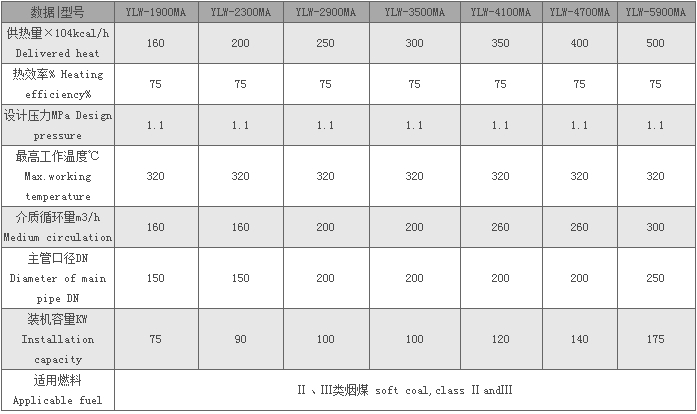

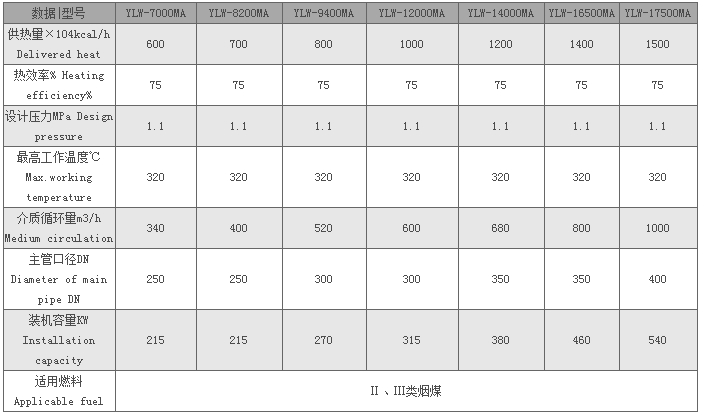

供熱量1900-23000KW,設計壓力1.1MPa

Delivered heat:1900-23000KW design pressure:1.1MPa

注:由于本公司產品不斷改進,以上產品參數將不斷更新,本頁所列僅供參考。表列鍋爐品種為本廠代表產品,如需其他型號參數鍋爐可參閱有關圖紙資料

Parameters listed herein are just for reference as those are subject to continuous modification with prduct upgrading.

Listed models are typical.If other models are needed,please refer to drawings and data available.